|

| February 26, 2013 | Volume 09 Issue 08 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

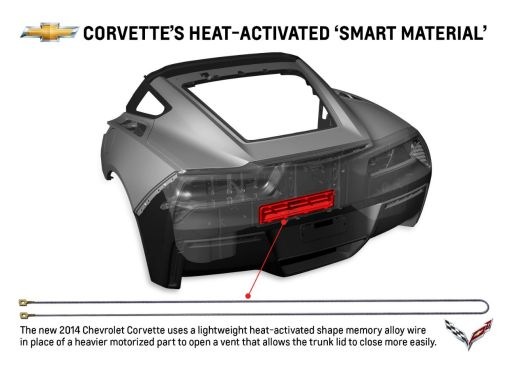

Chevrolet debuts lightweight shape memory material on Corvette

GM's first use of a heat-activated shape memory alloy replaces a heavier motorized part.

From its fiberglass body in 1953 to its aluminum chassis for 2014, the Chevrolet Corvette has a six-decade track record for introducing lightweight materials that improve vehicle performance. With the 2014 Corvette's aluminum frame weighing 99 lb lighter than its predecessor, that trend just keeps going.

The 2014 Corvette Stingray is the most powerful standard model ever, with an estimated 450 hp (335 kW) and 450 lb.-ft. of torque (610 Nm). It is also the most capable standard model ever, able to accelerate from 0 to 60 mph in less than 4 sec and achieve more than 1g in cornering grip. It is expected to be the most fuel-efficient Corvette, exceeding the EPA-estimated 26 mpg of the current model. [Image: GM]

In addition, the redesigned seventh-generation sports car is the first vehicle to use a General Motors-developed lightweight shape memory alloy wire in place of a heavier motorized actuator to open and close the hatch vent that releases air from the trunk. This allows the trunk lid to close more easily than on the previous models, where trapped air could make the lid harder to close.

Considering there are about 200 motorized movable parts on the typical vehicle that could be replaced with lightweight smart materials, GM is looking at significant mass reduction going forward.

Shape memory alloys, typically made of copper-aluminum-nickel or nickel-titanium, are smart materials that can change their shape, strength, and/or stiffness when activated by heat, stress, a magnetic field, or electrical voltage. Shape memory alloys "remember" their original shape and return to it when de-activated.

In the new Corvette, a shape memory alloy wire opens the hatch vent whenever the deck lid is opened, using heat from an electrical current in a similar manner to the trunk lights. When activated, the wire contracts and moves a lever arm to open the vent, allowing the trunk lid to close. Once the trunk lid is closed, the electrical current switches off, allowing the wire to cool and return to its normal shape, which closes the vent to maintain cabin temperature.

"Smart materials like shape memory alloys offer new possibilities for many movable vehicle features," says Jon Lauckner, GM's chief technology officer. "These new materials enable innovative designs and new and improved features at a lower cost than traditional motors and actuators."

Shape memory alloys also help remove unwanted mass, which can help improve vehicle performance and fuel economy. The wire actuator used on the new Corvette is approximately 1.1 lb (.5 kg) lighter than a conventional motorized system.

"The shape memory alloy used on the new Corvette represents nearly five years of research and development work on smart materials for which GM has earned 247 patents," says Paul Alexander, GM smart materials and structures researcher. "And it is just the beginning. We have many more smart material applications in the pipeline that will bring even more improvements to our vehicles going forward."

How shape memory alloys work: A super-basic (and fun) primer by Ainissa Ramirez, TEDEducation

Source: GM

Published February 2013

Rate this article

View our terms of use and privacy policy